EPL 3/5 AXIS XPR

High Quality, Long Lasting Performance

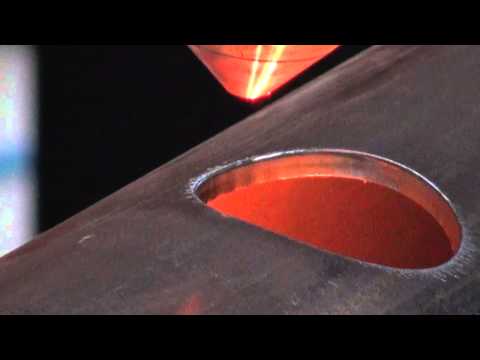

EPL Plasma series cutting machines, which you can safely use for many years thanks to their powerful body with dynamic and static rigidity, processed with high precision, add strength to their power with Hypertherm technologies. EPL Plasma cutting machines, which are offered with XPR and HPR series power options according to customer needs, provide more than 40% increase in consumable life and more than 50% savings in operating costs.

You can have an advanced solution by cutting multiple angles with the optional 5-axis cutting technology. Offering perfect solutions in vertical and bevel cuts, the 5-axis automatic angle adjustment technology provides time savings for the operator, while eliminating the errors caused by the operator. Even if the conditions in the production area are tough, you got the power with EPL Plasma.

ELECTRIC PANEL / PLATFORM

The control panel has a mobile design and can move independent of the bridge.

HYPERTHERM HPR400 XD POWER SUPPLY UNIT

HyPerformance® plasma welding offers its users high efficiency as well as high quality and precise cuts.

Read moreHYPERTHERM XPR170 POWER SOURCE

The XPR170™ represents the ultimate level in Hypertherm's cutting-edge plasma cutting technology, delivering huge savings in operating costs.

Read moreHYPERTHERM XPR300 POWER SOURCE

The XPR300™ represents the ultimate level in Hypertherm's cutting-edge plasma cutting technology, delivering huge savings in operating costs.

Read moreLIGHT BODYGUARD

Leuze M 4000 backlight protection curtain that complies with CE standards, ensuring safe operation.

BODYGUARD CAAF

With the cage barrier system built around the machine, external access to the moving parts of the machine is prevented.

EMERGANCY STOP CABLE AROUND THE GANTRY

Thanks to the security cable around the bridge, the machine can be stopped when the cable is pulled by the operator or someone around in case of an undesired condition.

5-AXIS CUTTING HEAD

All angles are calculated automatically with the 5-Axis cutting technology. During cutting, it automatically generates the angle value that the operator must enter manually.

Read moreCOMPACT TABLE

Integral design of the cutting table and the machine body in smaller machines.

Read moreWATER TABLE

The inner part of the cutting table allows you to cut while filled with water up to the surface of the plate.

ELECTRIC PANEL COOLER

Coolers or heaters can be installed on the electrical panel according to operation environment.

HYPERTHERM EDGECONNECT TC CONTROLLER

EDGE® Connect, Hypertherm's latest Computer Numerical Control (CNC) platform, provides unrivalled reliability, powerful embedded capabilities, and a high level of customization.

Read moreI-CUT PLATE

Offers an optimum solution for all your needs with its advanced precision cutting quality, production line, and automation compatibility.

Read moreI-CUT PLATE + PIPE

EPL Plasma series have been designed to precisely cut pipes with a diameter of 50 - 400 mm with pipe cutting technology.

Read moreI-CUT PLATE + PIPE + PROFILE

Ermaksan has designed the EPL Plasma series to precisely cut pipes in standard with a diameter of 50 - 400 mm, 400x400 square profiles and 100x150 rectangular profiles with pipe cutting technology.

Read moreTRUE BEVEL + TRUE HOLE

Ermaksan has designed the EPL Plasma series with pipe cutting technology to precisely cut pipes with a diameter of 50 - 400 mm.

Read moreTRUE BEVEL + TRUE HOLE + BEVEL PIPE

Has been designed to precisely cut pipes (straight and angled) with a diameter of 50 - 400 mm with pipe cutting technology.

Read moreTRUE BEVEL + TRUE HOLE + BEVEL PIPE + BEVEL PROFILE

The Plasma series have been designed to precisely cut pipes in standard with a diameter of 50 - 400 mm, 400x400 square profiles and 100x150 rectangular profiles with pipe cutting technology.

Read moreMARKING PEN

As a pneumatic system, it can be used to draw figures or write with hard-tipped dot strokes on flat surfaces with dot strokes.

MITSUBISHI DIGITAL AC SERVO MOTOR

A double-driven synchronous motor, and a single-driven AC servo motor in accordance with CE and CSA standards are used on Y and X axes, respectively.

OXY CUT

Oxygen cutting machine is suitable for heavy duty and general use in medium and higher thickness. It allows users to perfectly cut sheet metals up to 300 mm depending on the user's demands. Users of Pronest advanced nesting software supplied with the machine will benefit from the feature of programming more than one cutting process.

Read moreOXY CUT ±45° MANUAL ANGLE CUTTING APPARATUS

Oxygen cutting torch is a manual system that allows cutting with a maximum of ±45 degrees in horizontal and vertical direction, depending on the manual angle apparatus.

ANGLED PIPE CUTTING

Ermaksan has designed the EPL Plasma series with pipe cutting technology to precisely cut pipes with a diameter of 50 - 400 mm.

Read moreSTRAIGHT PIPE CUTTING

Ermaksan has designed the EPL Plasma series with pipe cutting technology to precisely cut pipes with a diameter of 50 - 400 mm.

Read moreROTARY TUBE PRO SOFTWARE

Rotary Tube ProTM provides a complete design and cutting solution for tube and pipe pieces without the need for 3D CAD experience.

Read moreCORE GAS CONSOLE

Has an unrivalled black steel cutting performance and superior angle adjustment and edge finishing ability on stainless steel up to 12 mm.

Read moreVWI GAS CONSOLE

There is a ventilated N2 plasma and an H2O enclosure in this VWI (Vented Water Injection) patented system.

Read moreOPTIMIX GAS CONSOLE

In addition to Core and VWI consoles, this is a split 3 gas (Ar, H2 and N2) mixing system used for providing flexible construction, superior stainless steel and aluminium cutting ability.

EXPANDED BRIDGE MANUAL ± 45° ANGLE CUTTING APPARATUS

When a manual angle apparatus is attached to the plasma or oxygen cutting torch in the extended bridge machine, the machine bridge can be extended and the machine length can be increased.

Read moreSTANDARD BRIDGE MANUAL ± 45° ANGLE CUTTING APPARATUS

When a manual angle apparatus is attached to the plasma or oxygen cutting torch in the standard bridge machine, full distance full length cutting losses are experienced due to the angled stance of the torch.

Read morePLATESAVER

PlateSaver technology enables the use of new, special-purpose I/Os for CAM software when programming jobs for XPR-equipped machines.

Read moreRAPID PART

Rapid Part technology provides superior performance to your operators, your company, and also to your budget.

Read moreNETWORK INTERFACES AND USB PORT FEATURE

It is possible to set up a network connection with the controller. With this connection, it is possible to remotely access to the machine.

Read moreRETURN FEATURE

When an undesirable situation occurs during cutting or when we need to bring the machine to a different position, this feature allows us to return to the last point where cutting was stopped.

METRIC AND INCH FEATURE

It is possible to switch between metric and inch systems on the machine software.

POINT LASER LIGHT FEATURE

Thanks to the laser light, it allows us to see more clearly where the torch is.

Read moreAUTOMATIC CUTTING HEIGHT CORRECTION SOFTWARE

Automatically detects and corrects arc voltage changes during plasma cutting.

Read morePLATE ALIGNMENT FEATURE

It is the feature that allows the workpiece or plate placed arbitrarily on the cutting table to be aligned by reference from two corners by meanss of a torch or a laser light.

NEUGART PLANET TYPE REDUCER

High acceleration levels are achieved thanks to the servo motor, driver, and reducer with high precision reaction times.

Read morePRONEST SOFTWARE

ProNest is an industry leading CAD/CAM nesting software designed for advanced mechanized cutting.

Read morePRONEST (BEVEL MODUL) SOFTWARE

The Bevel Machine Interface allows you to create NC output for pieces with various types of bevel edges, including multi-pass bevel cuts, for cutting machines equipped with a programmable bevel head.

Read morePRONEST (BRIDGE CUT) SOFTWARE

In plasma cutting, it starts to cut the other piece's inlet before chain cut blasting.

PRONEST (CHAIN CUT) SOFTWARE

In oxygen cutting, it starts to cut the other piece's inlet before chain cut piercing.

HIGH CUTTING QUALITY

XPR combines new technology with refined cutting processes for next-generation, X-DefinitionTM on black sheet, stainless steel and aluminium, and carries the HyDefinition cutting quality to the next level.

LONG-TERM SAVINGS

Thanks to the advanced power supply technology, system feedback is provided. It intervenes automatically to eliminate conditions that negatively affect system efficiency and consumables' life.

LOW ENERGY CONSUMPTION

Has been designed taking energy efficiency and minimal resource use into consideration. Thus, while increasing productivity and savings, the effects on the environment are kept at a minimal level.

EASY OPERATION

Optimized cutting parameters are automatically set and controlled in a single step without operator intervention to ensure consistent results.

LOW OPERATING COST

Over 40% increase in consumable life and more than 50% savings in operating costs.

FLEXIBLE SOLUTIONS

While offering flexible solutions to its users with its structure suitable for automation, it also provides the operator with ease of use.

Similar Products

Check out the other products in the category!

SMART PLASMA

It is a quality and economical plasma cutting machine that meets your needs by using plasma and oxygen cutting technologies.

View product