Why should you invest in automated laser solutions?

An automated laser cutting solution can bring to companies expanding manufacturing capacity more than 60% depending upon the material, thickness, size, nesting, etc. These automation systems are major influence on the manufacturing economy and will increasingly continue to be over the next years.

Investing in laser automation has numerous superior characteristics. Incorporating smart laser automation into your metal fabrication divisions means utilizing technology to intelligently streamline many functions of your factory besides to invest in the saving.

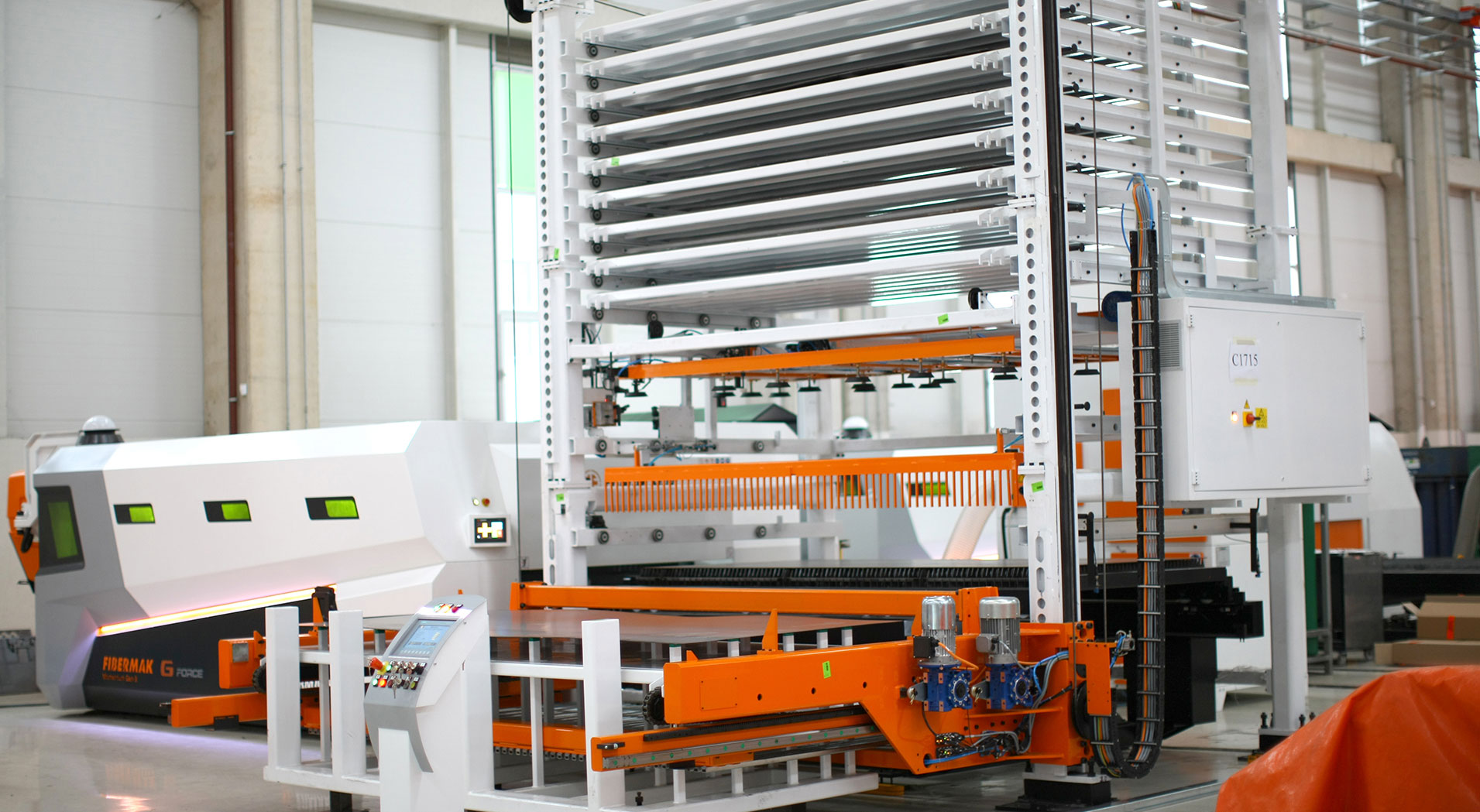

Ermaksan has a range of special solutions for very particular laser automation requirements. The demand for high power laser cutting machines in larger formats and with automation systems are increasing. These more efficient systems mean that maximum productivity and profitability for the customers. Some of benefits of laser automations for firms:

One of the many benefits of automation is reducing manual labour costs. Within metal manufacturing divisions, laser automations have led to increased labour productivity as fewer workers are needed to produce the same number of manufactured goods. Based on the level of automation, from material handling, inspection to supervision would decrease the labor cost significantly.

Products and parts are getting customized and big batches are getting smaller. The new tendency side higher customized products and smaller batches production. So, our customers need solutions and adapting for this trend to produces small batches in a flexible automation system.

Automated systems that increase consistency and reduce scrap rates can be further engineered to inspect parts before they proceed through the rest of the manufacturing process.

The laser automation systems are highly accurate, it could do intricate details and complex work on sheet metals. It is also precise and can do the job repeatedly.

The laser cutting machines allowing continuous mass production capability and efficiency with its tower systems due to zero idle time and short changeover time. Can improve safety and higher labor productivity and remove risk of human error and. The system ensures high level of reliability, high flexibility, and ease of use.

All the components on the machine are collected on a common network so that their data may be accessed easily. Eliminate idle time costs with predictive maintenance at ER 4.0 software aided machine. Also, data collection improves accuracy and reduces costs. Such increased accuracy enables company managers to make better decisions.

Consequentially, the key question is whether the up-front cost to implement laser automation will pay off within the lifecycle of the system. Calculating return on investment for an automated or manual system is important to understand which one is right for your process. Ermaksan’s professional team will help you determine the right combination of machines, towers, conveyors and loading systems.