Speed up your additive manufacturing with ENAVISION TWIN

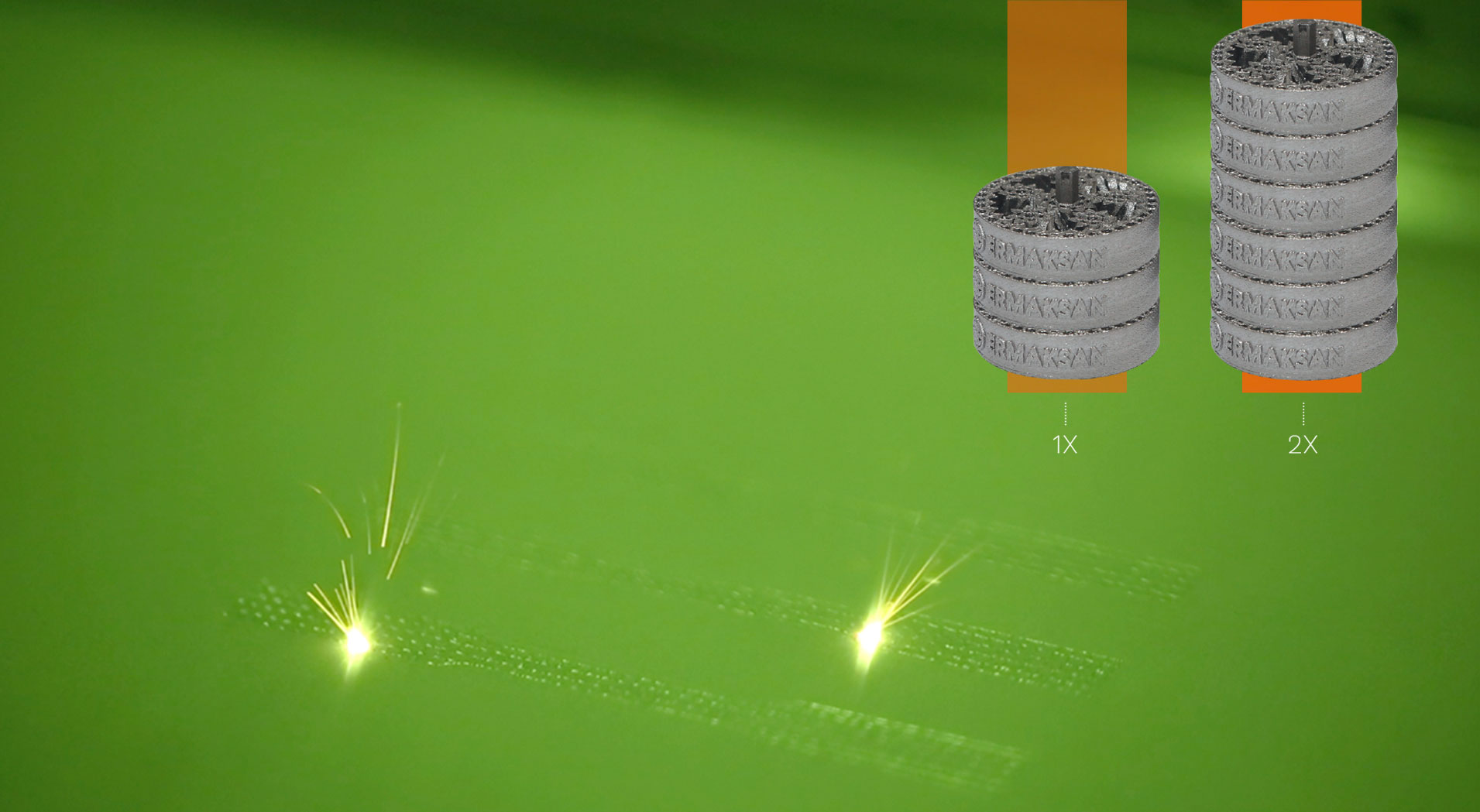

With ERMAKSAN’s Modular Dual Laser technology, you can increase your productivity up to 90% at any time. You can have a faster production capacity up to two times in the first machine investment or in the second investment that you’ll make thanks to modular system.

Production time is reduced in half with ENAVISION TWIN additive manufacturing machines, which enable double laser scanning to the same production area. Thus, the production efficiency can be doubled. Instead of production with two machines, a machine investment having a Dual Laser Technology completes your production without the need for a 2nd machine. The machine thanks to Galvano head enables a homogeneous manufacturing process through the production platform.

In this system, which works with selective laser melting technology, users can perform a more precise production. The process sinters the powder, layer by layer. Extremely efficient Dual Laser Technology can be used for producing parts without any deficiency in density of parts as well as a number of parts in a single parcel. The machine has 2 x 500-Watt EON laser power source by Ermaksan as a standard feature. In addition, customers can enlarge the laser sources 2 x 750 watt or 2 x 1 Kw as an option.

Production is realized by converting the data embedded in the work file prepared in Materialise Magics into physical orders via the Materialise MCP module. Ermaksan BP (Build Processor), Designed and optimized in partnership with Ermaksan and Materialise, provides great convenience to its users. In addition to the standard parameters offered by Ermaksan, it provides extensive opportunities especially for R & D and research institutes with more than 120 open parameter structures that offer flexible working opportunities to users.

The operator control panel for the ENAVISION series additive manufacturing machines, which ensures significant benefits for user to print faster and more efficiently. The CNC panel developed for ENAVISON by considering operators’ needs comes forward with its being fast, precise, robust as well as productivity, functionality and conformity with Industry 4.0 features make it unique. Besides, it prevents operator errors by simplifying the complicated workflows. As well as all the software designed and developed by EON Photonics, a sister company of Ermaksan that offers flexible work arrangements into their unique business needs.